Watermaker made by professionals.

Reliable and proven for years. Worldwide.

Advantages of watermaker on cruising yachts and ships

- drinkable water in best quality

- ample showers in soft water

- less weight, more sailing performance

- enjoy live on board with fresh water

- smaller water tanks save weight and fuel

- doing the laundry and washing the dishes with fresh water

- cruising everywhere without having problems with fresh water

- never buy poor water or water containing too much chlorine

- never stow again containers with drinking water from the supermarket on board

The possibilities are endless

Why AQUATEC?

Quality Built on Tradition

At Aquatec, we stand for reliable and high-performance seawater desalination plants for yachts and commercial vessels-

designed for global operation and the highest standards.

What started as an idea in the early 90s has grown into a family business where three generations actively work together today.

We combine decades of hands-on maritime experience with technical expertise and an uncompromising commitment to quality.

Our watermakers are built exclusively with high-quality and meticulously tested components.

We deliberately avoid failure-prone electronics and instead rely on mechanically robust, maintenance-friendly designs.

This makes our systems exceptionally durable and reliable.

We provide comprehensive support, from selecting the right system and installation to maintenance and technical service.

For us, what truly matters is honest consultation, personalized assistance, and products that deliver on their promises.

Get in touch!

We will be happy to help.

Michael Matz

- All plants in stock.

- Quality made in Germany at reasonable prices

- 100% availability of all parts.

- Daily express shipping - worldwide

- Support provided directly by manufacturer.

- Based on our many years of experience in servicing watermakers, we have decided not to use any

electronics to control our own watermakers.

Operating without electronic control is straightforward and reliable.

This concept is often confirmed by customers with long cruising experience, who opt for a desalinator of this design.

A combination of high-quality components.

This German-made desalinator is designed for reliable, long-term operation without failure.

By limiting the components to those absolutely necessary for a desalination plant and doing without electronics, trouble-free operation on board your yacht or ship is ensured for years.

High-pressure pump head made of duplex stainless steel (1.4462).

Following careful material research and drawing on our experience with watermakers since 1990, we manufacture the pump head, the heart of our high-pressure pumps, from 1.4462 duplex stainless steel.

Control panel Aluminium

Made of aluminium.

Choose between silver anodised or anthracite powder-coated.

A mounting frame for flush installation is available as an option for all AC units.

Pressure control valve in Duplex stainless steel 1.4462

This control valve has been developed exclusively for our watermakers and reliably ensures a constant working pressure, even when there are voltage fluctuations in the onboard power supply.

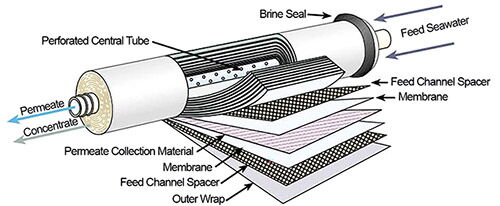

Proven for years: membranes and high-pressure vessels.

The proven Seawater 2540 industrial membranes are available worldwide.

The membrane housings (pressure vessels), which are manufactured on a large scale from GRP, ensure an unlimited service life..

In natural sciences and technology, osmosis is perceived as the directed migration of molecules through a semi permeable membrane. The chemical and physical structure of the membrane determines which molecules are able to pass and which are not. For this reason, it is called semi-permeable, which means as much as halfway or partial permeability.

If one mixes different liquids, like in this case water with different salinities, they aim to equalize their concentration. That way, the seawater would be thinned out and the drinking water would be enriched with salts. The effect would be a less concentrated, homogeneous dissolution. Pouring sea- and fresh water in equal amounts into a container where both liquids are separated by an adequate semi-permeable membrane, there would be one side with seawater that is highly loaded with salts, on the other side more or less “clean” water without or with little dissolved components.

The natural tendency of both liquids to equalize their salinity leads to the migration of water molecules from the fresh water side towards the seawater side. As a result, the volume of water on the fresh water side decreases while it increases on the seawater side. This process of osmosis takes place until the pressure on the seawater side is in accordance with the osmotic pressure. Then it stops. In this case, the osmotic pressure is around 30 bar.

The described process however is reversible by exposing the liquid on the seawater side to mechanical pressure. At a pressure of 30 bar, the osmotic process cannot take place or would rather be reversed. When pressure is increased beyond 30 bar, for instance 60 bar, water molecules from the seawater side migrate to the fresh water side. All other components of the seawater dissolution are not able to pass the membrane. As a result, the dissolution on the seawater side remains highly-concentrated while there is a gain of fresh water on the other side of the membrane. This process is referred to as reverse osmosis (R.O.)

The seawater is delivered to the pressure pipe’s entry side of a RO-system by a high-pressure pump. The osmotic membrane is located in the pressure pipe and is merely permeable for the vehicle “water “(solvent) and detain the solute substances. When the pressure difference is more than leveling out the osmotic head, the water molecules are able to pass the membrane that works like a filter, while the “unpurified” molecules are detained. In opposite to a classic membrane-filter, osmosis membranes do not have continuous pores. In fact, the ions and molecules are migrating through the membrane by diffusing through the membrane material.

Inside of the membrane, the permeate-tube is located which transports the product-water (permeat) through one of the two end caps of the pressure pipe towards the fresh water tank. The excess seawater, now referred to as concentrate (brine), is drained off overboard through the outlet of the pressure pipe by a pressure control valve.

Customer feedback

We purchased a 12V, 85 l/h watermaker from you.

It's still working perfectly, and we've already produced over 66,000 litres of water!

Patrick Heini, SY Allure. "Watermaker DC 800"